It's been sitting quiet happily in the cupboard.. I was going to move it into the shed but due to the really unusual weather here the last few days, the shed was like a sauna! *ohhh gets idea for next project*

The bottles seem to have some fizz in them now, and can feel some pressure in the bottles but nothing to worry about as these PET bottles can hold up to 100 PSI anyway.. no bottle bombs here!

So they are just being kept indoors, same place but with the temperature a bit cooler in the room.

I have however, moved 2 bottles into the fridge earlier this afternoon and now they are nicely chilled.

I had marked the first bottle poured.......

Couldn't resist... so had to open it!!!

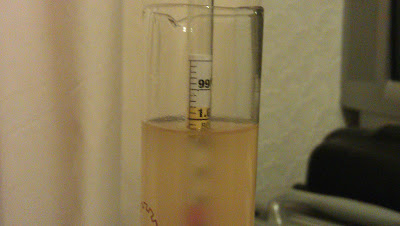

Looks - Well it's relatively clear, bottle had some fizz but that will improve over time.

Taste - It's drinkable, not really got a bad after-taste and goes down pleasantly enough.

I would say it would definitely needs a bit longer sitting to improve and my plan now is to leave it a few weeks and get started on the next kit.

Though I am going to finish this bottle, would be rude not too!